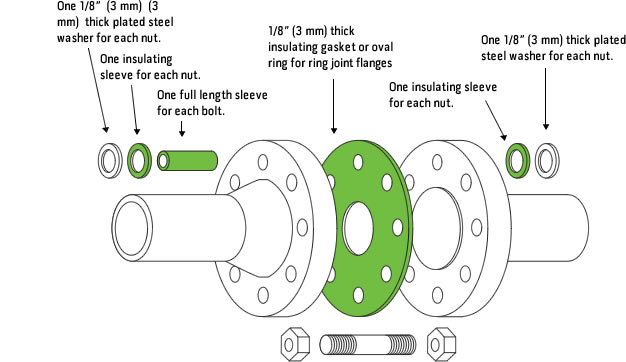

FLANGE INSULATING SETS

Premium grade high dielectric strength materials ensure the flange joint is designed to withstand the maximum electric stress without breakdown. Other materials available upon request.

GASKET MATERIAL |

||||

| ASTM TEST METHOD | PROPERTIES | PLAIN PHENOLIC | NEOPRENE COATED PHENOLIC | G10 |

| D149 | Di-electric strength | 400-500 V/mil | 400-500 V/mil | 550 V/mil |

| D695 | Compressive strength | 30,000 Psi | 50,000 Psi | 55,000 Psi |

| D228 | Water absorption | 1.60% | 0.75% | 0.12% |

| D257 | Insulation resistance | 45,000MW | 100,000MW | 200,000MW |

| D790 | Flexural strength | 22,000 Psi | 27,000 Psi | 66,000 Psi |

| D256 | Izod impact strength | 10KJ/m2 | 10KJ/m2 | 15KJ/m2 |

| D638 | Tensile strength | 17,400 Psi | 17,400 Psi | 45,000 Psi |

| Temperature | -54 to 107 OC | 100 0C | 150 0C | |

SLEEVE MATERIAL |

|

| G10 | MYLAR – SLEEVES |

| 550 V/mil | 4000 V/mil |

| 55,000 Psi | – |

| 0.12% | 0.22% |

| 200,000MW | – |

| 66,000 Psi | 13,000 Psi |

| 15KJ/m2 | – |

| 45,000 Psi | – |

| 150 0C | 176 0C |